Ventilation, Mechanical Piping & Plumbing

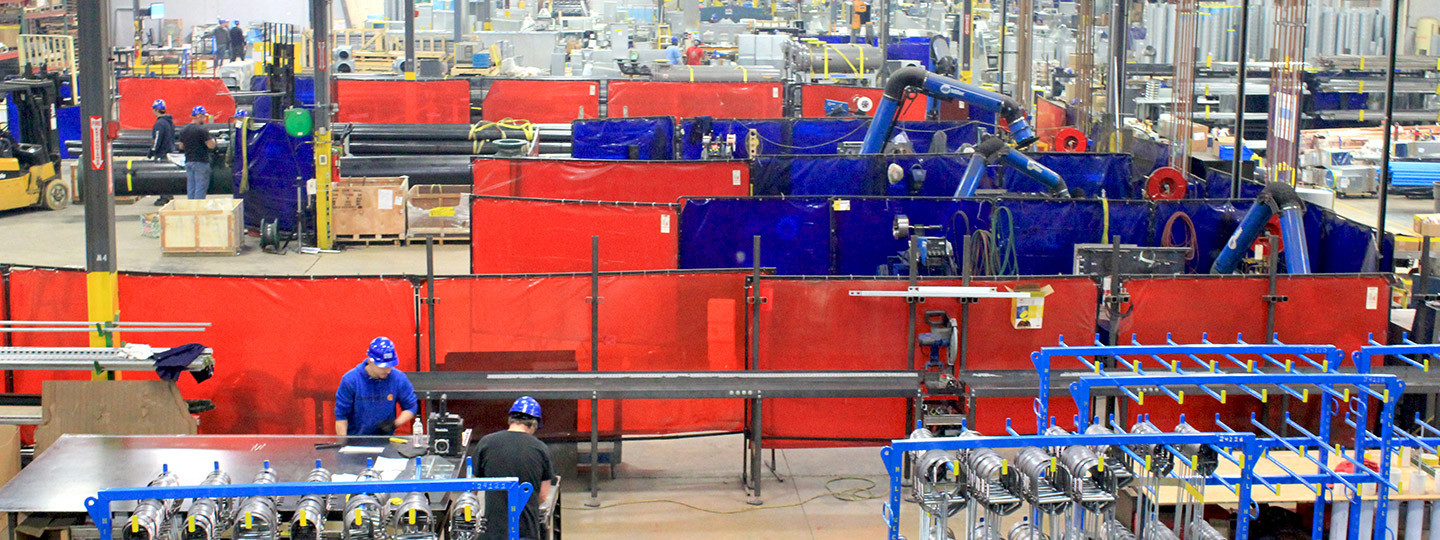

Fabricating within our shops allows for our employees to work in a safe and controlled environment that ultimately increases project efficiency, provides better quality, enhances project safety and reduces cost by using consistent practices in a coordinated effort by our team. Limited only by project logistics, our project teams are driven to evaluate all project fabrication opportunities and to implement those that add value to any given project.

Hill’s BIM technology addresses system coordination as well as fabrication. Spool drawings are extracted from the project models considering project and cartage logistics, which allows for the necessary accuracy required to facilitate system fabrication within our state-of-the-art facility.

The Hill team regularly performs the pre-fabrication of the following systems:

Additional benefits to utilizing prefabrication include just in time deliveries, project schedule enhancements to better address critical path activities and trade stacking, a reduction to the on-site workforce and a reduction in project deliveries and congestion.

All of the company’s fabrication activities are completed in-house by Hill’s team of skilled, union, trade professionals.

Ultimately our intent for shop fabrication activities is to provide the most cost-effective systems’ installations, on-time, with the highest quality and in the safest manner, all in effort to help facilitate the project team’s delivery program. Maximizing shop fabrication opportunities in our opinion is a key to the success of any given project.

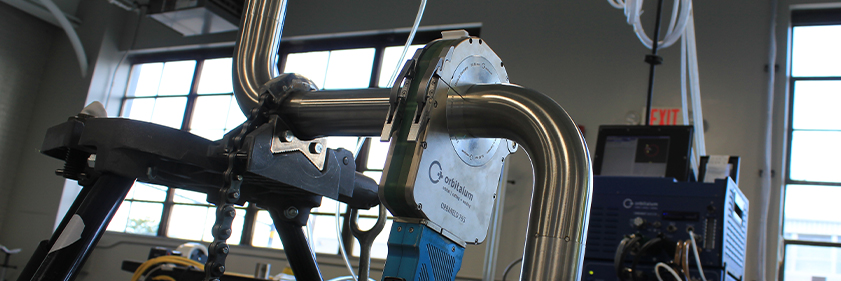

Process Piping

Process piping means piping systems and their component parts, that are not building services or power piping systems, and that may be installed in petroleum refineries, chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants, and related processing plants and terminals.

The Hill Group prides itself in prefabrication of mechanical systems and has taken it a step further in providing process piping systems to our Chicagoland customers. With a dedicated 10,000 square foot, state of the art clean room production space, your systems are guaranteed to meet the highest level of purity standards.